Aluminium

Aluminium

Our further processing

We have focused. For the areas of Automotive Solutions and Industry-Solutions we have a comprehensive range of state-of-the-art processing possibilities at our disposal.

CNC Machining

Economic components require structured processes. With our high-speed systems we machine your components in three, four or even five axes! We optimise the process with shuttle tables and minimum tool change times.

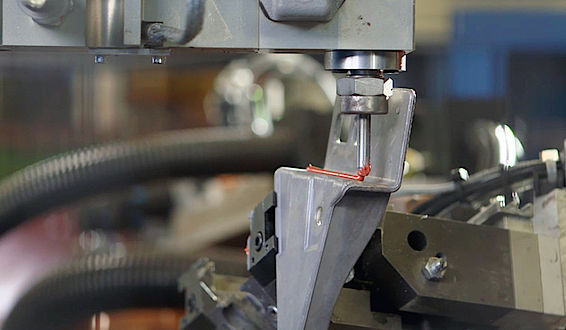

Punching

Even with "medium series" a punching process is worthwhile. Whether chambers, flanges or webs, we cut profiles reproducibly and precisely within the process. The integration of bending operations or forming increases the economic efficiency.

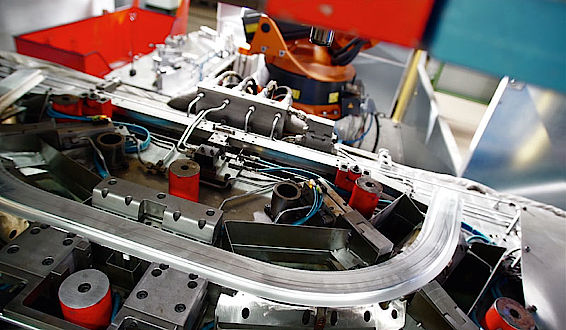

Stretch Bending

We use the latest technology and have the necessary know-how. The most complex 3D geometries are brought into shape using our stretch-bending machines. In addition, we offer the possibility of manufacturing your workpieces using the roll bending, flex bending and die bending processes.

Welding

Welding processes and hybrid joints - such as weld bonding - are carried out on our highly automated systems.

Bonding and Riveting

The demands to constantly reduce consumption can be met by a multi-material design. We connect with the help of robots through the processes of gluing, riveting, punch riveting and press-fitting.

You can find more information about our aluminium products here.